|

Products

|

Products  Cutting Saw for Aluminum Doors and Windows

Cutting Saw for Aluminum Doors and Windows

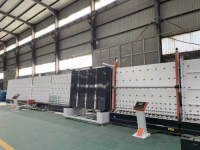

vertical automatic multi-functional insulating glass production line Model:WLBZ2025CB

vertical automatic multi-functional insulating glass production line Model:WLBZ2025CB

Available

Available

·Coating inspection adopts new technology, new materials, and contact probe structure to detect and identify the function of LOW-E coated glass layer, and has a self-stop transmission function when the coating layer is wrong ·The overall material of the cleaning section is a stainless steel shell of industrial

·Coating inspection adopts new technology, new materials, and contact probe structure to detect and identify the function of LOW-E coated glass layer, and has a self-stop transmission function when the coating layer is wrong

·The overall material of the cleaning section is a stainless steel shell of industrial plate, and the base of the brush bearing is made of stainless steel. Brush shaft

It is a self-aligning bearing with long service life and high precision.

The brushes are equipped with a special coated LOW-E brush.

European Italy technical brush drive mode, three groups of six brushes, the power is driven by six independent motors, hair

The brush operation is stable and efficient.

The cleaning machine adopts a water purification spray system with 6 brushes, two-stage cleaning, and a stainless steel water baffle in the cleaning chamber to prevent cross-contamination of the brush rotating water flow.

The rubber roller of the washing machine is made of acid and alkali resistant rubber roller, and the spacing can be adjusted according to the glass of different thicknesses.

The drying area (air knife room) is equipped with a water mist separation device to eliminate the possibility of floating water mist (oil molecules) when the glass passes through the strong wind pressure splashing water drying area, and the natural light will produce bright spots after the oil molecules adhere to the glass surface.

The air knife using Germany Bystronic technology can be manually adjusted according to the glass thickness.

Equipped with high-power high-pressure silent fan, equipped with air heating function, circulating air, glass air-drying speed is fast and the effect is good.

·The conveying part is two conveyor motors, and two pieces of glass can be stored at the same time in the cleaning waiting section, and the equipment program will automatically default to a large piece of glass, and the two are automatically switched to be automatic and efficient, and the size of the glass can be automatically identified, so as to improve the processing capacity of the production line itself.

The back plate of the conveying section is made of double-sided polyurethane resin coated high-strength board, which has strong corrosion resistance and good flatness.

The conveying part adopts the buffer parking function, avoids the phenomenon that the glass collides with the equipment positioning, and reduces the wear of the glass to the conveying wheel.

The insulating line conveyor part is equipped with the function of glass running and reversing to meet the requirements of glass processing technology, such as re-cleaning after glass surface treatment.

·The guide rod of the laminating machine is made of aluminum alloy special profile, which is easy to adjust; Aesthetically pleasing with LED inspection tubes.

It is equipped with an aluminum frame positioning mechanism, a spring positioning device and an aluminum frame positioning scale, which can be applied to the adjustment of different thickness glass and gluing depth.

·It can process double-layer, three-layer insulating glass, four-layer insulating glass, louver insulating glass

Joining does not require manual assistance, ensuring operational safety and efficiency.