|

Products

|

Products  Cutting Saw for Aluminum Doors and Windows

Cutting Saw for Aluminum Doors and Windows

Vertical insulating glass automatic sealing line

Vertical insulating glass automatic sealing line

Available

Available

Max. glass size 2000x3000mm Min. glass size 300x180mm IG Unit thickness

| Max. glass size | 2000x3000mm |

| Min. glass size | 300x180mm |

| IG Unit thickness | 12-60mm(12-80mm) |

| Coating depth | 3-18mm |

| Aluminum frame width | 6-27mm |

| Coating speed | 5-40mm |

| Transmission speed | 5-50mm |

| Hydraulic pressure | <100kgf/cm |

| Air pressure | 0.6-0.8Mpa |

| Total power | 10kw |

| Overall dimension | 7300x2500x2900mm |

1. The electronic control system and servo system all adopt the Yaskawa control system of Japan, which has fast operation speed and stable operation of the equipment.

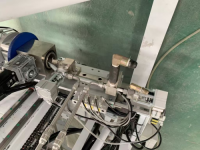

Use the dual system A plunger pump and B plunger pump to supply glue and switch system functions with one click. Customers can quickly switch between different types of glue, which is convenient and fast, and improves work efficiency.

2. Touch screen interface is adopted, which can realize manual operation and fault diagnosis.

3. The program has a memory function, and the glass parameters of different models can be called with one click.

4. The backrest conveyor wheel adopts inlaid type, and the glass runs smoothly.

5. Equipped with high-speed positioning function, the glass can be accurately positioned when conveying at high speed.

6 Hydraulic system glue supply and proportioning system, can provide stable glue output and accurate A and B component ratio.

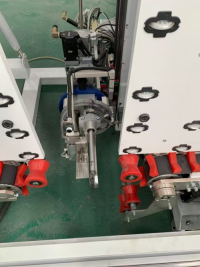

7. Automatic debinding function to avoid pipeline blockage caused by human factors.

8. Chain type V-block conveyor, so that the glass conveyor is smoothly positioned and accurate, and can reduce the phenomenon of conveyor belt sticking.

9. The whole line is equipped with an automatic detection glass thickness device, the hollow line thickness measurement data is transmitted to the sealing line, the conveyor belt is automatically opened in advance according to the glass thickness, and the glue head is automatically in place, without the need to choose double glass and three glass.

10. The operation interface is simple, suitable for popular operation, and supports rectangular double-glass, triple-glass and two-cavity glass gluing